This past summer, a study from New York University highlighted the future of 3D printing in the medical field. While most people may associate 3D printing with things like guns, computers, splints, in the medical community it’s being championed as a solution to bone replacement. The study showed that 3D printed bones have the potential to assist in the growth and re-growth of real bones.

Now, the University of Arizona is also staking its claim in the developing medical 3D printing world as a scientist from the college recently received a $2 million grant from the Department of Defense. The grant supports a five-year project for developing a 3D bio-printing process for helping bone fractures, much like the study at NYU. The research will utilize adult stem cells and bio-printing tech, and could, in time, be used by the military to take care of bone injuries.

“It kind of became a natural target because military personnel are often hurt in a way that causes them large bone damage. It’s much rarer for civilians to experience these long pieces of bone missing,” Dr. John A. Szivek, PhD, said. “You wouldn’t use this kind of technology with simple injuries as the bone can heal easily.”

Dr. Szivek will work with clinical partners at the University of Arizona’s Department of Orthopaedic Surgery. The majority of the work will center around printing bone-shaped scaffolds through the 3D printing process. These scaffolds will then be linked up with calcium particles in the body and stem cells to develop implantable scaffolds and push for faster bone growth and healing.

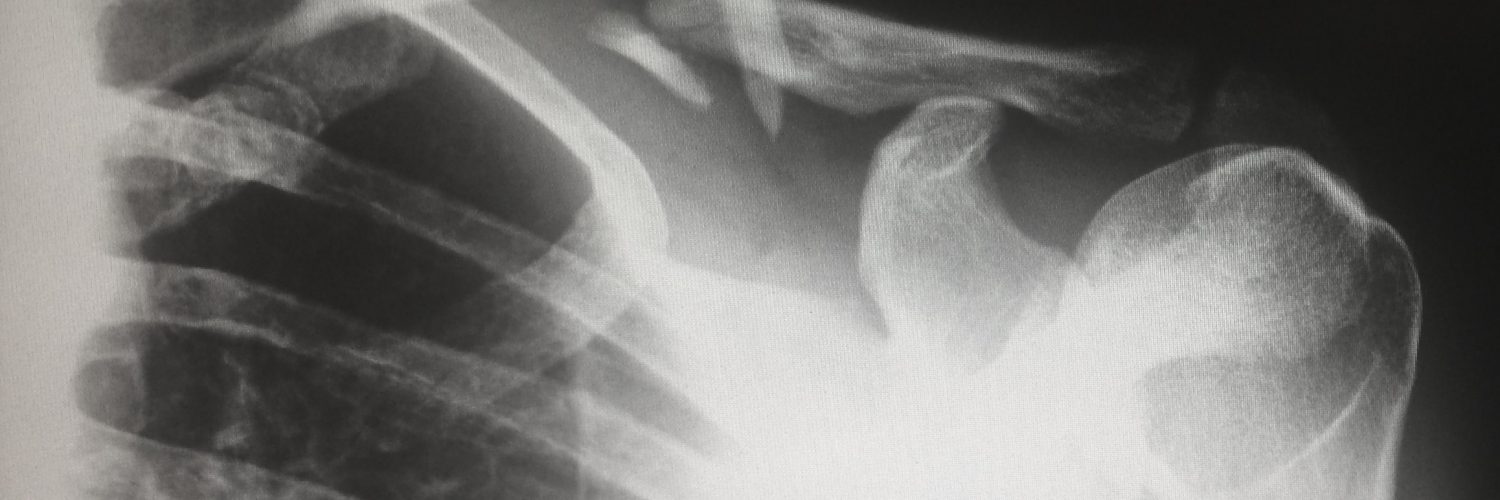

If a soldier suffers a literal bone-shattering blow to their shoulder, they are out of commission and have to be discharged. This kind of technology will step in and act as a liveable rehabilitation for their bones in real time.

“If we can regenerate bones so they’re the same as before the injury, they would be capable of doing what they can do before their injury. This tech has the potential to do that,” notes Szivek.

The researcher has been working with pilot studies for 3D-printed projects for about 16 years. The results in the bone regeneration project so far have been impactful and promising, showing complete bone formation, covering a large bone defect in about three to six months. The next step is to make the healing process even faster.

Dr. Szivek will look at how exercise impacts the 3D-printed bones in soldiers in rehabilitation. Will exercise too soon cause more harm than good? This is what the doctor and his researchers want to find out. So far, studies show that exercise actually helps bone growth.

“We’re already seeing faster bone growth than usual. If we can add in a component that can represent the right rehab, then we can get them to regrow bones faster and more normally,” says Szivek.

Dr. Szivek will implant small sensors into the 3D-printed implants. From there, the sensors will transmit the activity from exercise to the researchers so they can get a clearer picture as to the overall effect. What’s more, the sensors will help to analyze things like weight to better understand the load that 3D-printed bones can take, helping the researchers see just how much these bones can handle in the long run.

If these study trials prove to be even more successful, the next step will be to put the implants to actual use for military veterans injured in combat. The 3D-printed bones could have a huge effect on reducing the amount of surgeries needed to treat bone injuries entirely. Altogether this will save money, downtime, and provide a better healing process for soldiers.

Add comment